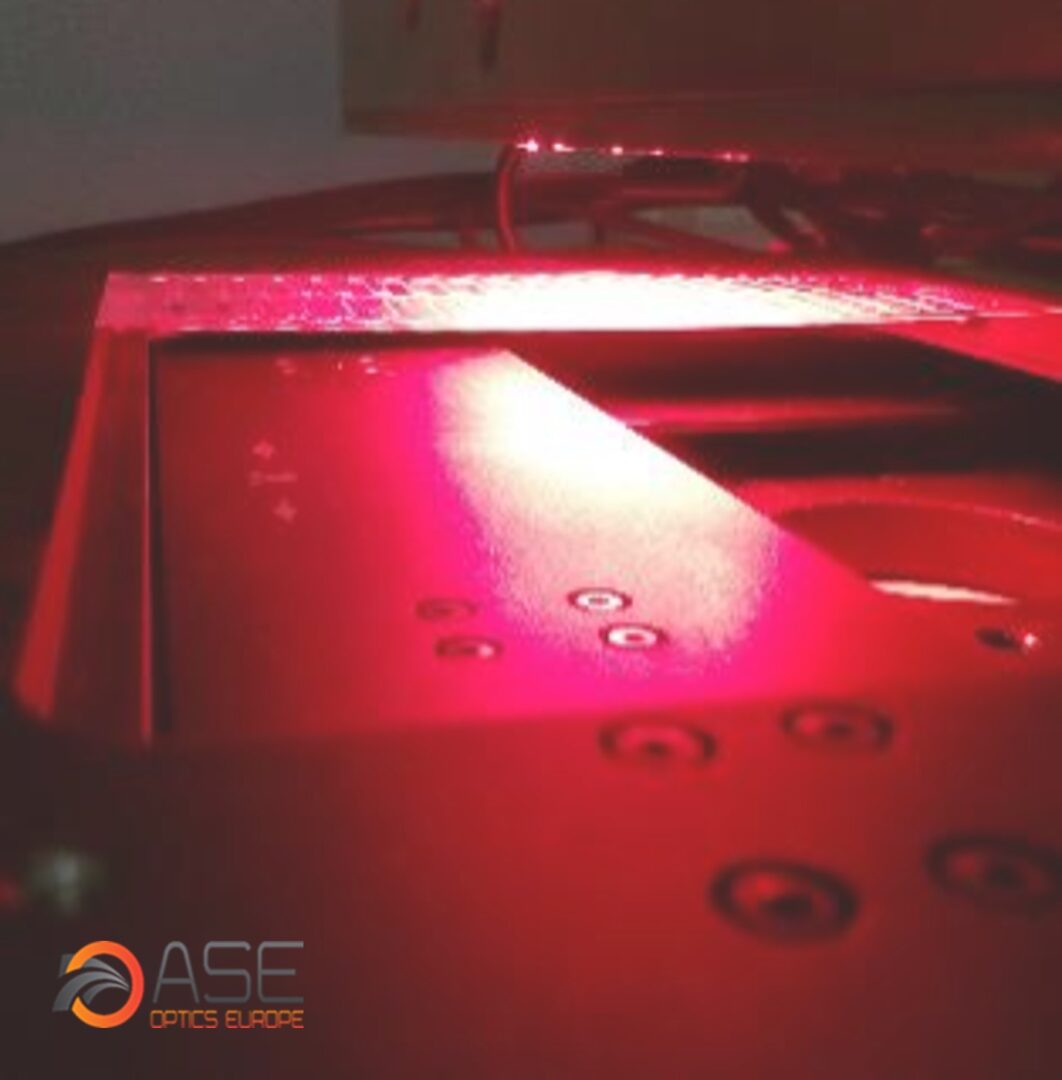

FASTTEST is an R&D project developed internally by ASE Optics to research and develop a non-destructive 3D inspection system for microfluidics and microdevices. The idea arose after our participation in the European Community’s Seventh Framework Program (FP7) – FaBiMed, where we were leaders of the “Quality Control and Inspection” work package.156

Which is faster? Does the fastest system do it?

The FASTTEST system performs a quantitative mechanical evaluation of the quality of micromachined parts on assembly lines, assessing the quality of the manufacturing process (conformity to mechanical specifications). The parts that are evaluated with FASTTEST have a dimension of a few mm in x-y and only a couple of mm in depth. The accuracy of the measurements is of the order of a few µm.

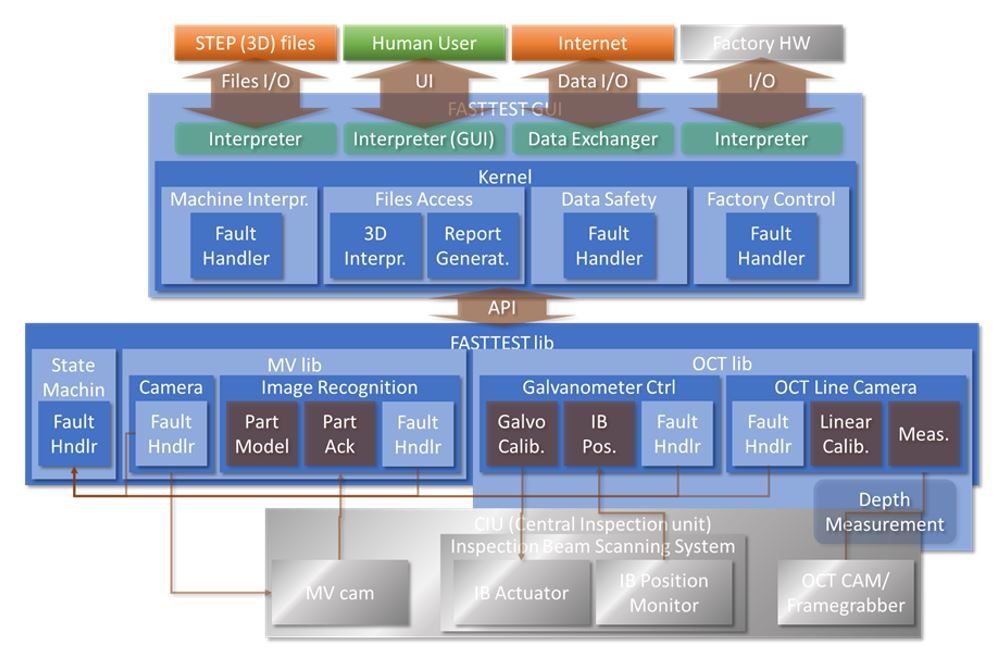

In the figure below, we present the schematic of the FASTTEST system as seen from the software architecture. In gray are the hardware parts of the system; in blue, the code sections; in red are the communication channels and data buffers.

The interpreter stages in the GUI are used to translate commands and data to/from the assembly string, external data files, the GUI itself and the functional core.

The beginning of the project

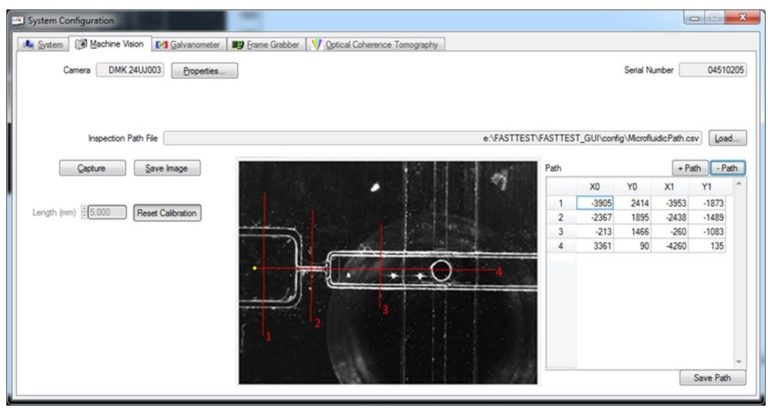

Since the beginning of the FASTTEST development project, work has focused on software integration and optimization of the different assemblies that make up the FASTTEST instrument. OCT and FFT measurement leading to depth measurements have been performed and calibrated. The OCT data acquisition rate is now hardware limited to 40,000 depth profiles per second. A user interface now allows the user to select the path that the OCT should scan.

The system can self-configure and perform measurement operations following an inspection path entered by the user. Machine vision is able to recognize patterns that will be used to automatically guide the OCT beam to the regions of interest. FASTTEST has been demonstrated to potential customers and discussions are currently underway with a medical device manufacturer about applying the system’s capabilities to a particular quality control problem that they have not been able to solve before. AI’s tailoring of the software to the specific needs of potential customers has increased the customer base for the FASTTEST system.

In the image above, we can see a 3D map of the portion of a syringe needle. The inspection area was selected through the software, which reconstructed the depth map in false colors (each color corresponds to a depth value, according to the color scale reported on the right of the image). Through FASTTEST, customers can schedule the relevant inspection route for quality assessment of the parts they manufacture, saving time and improving reliability.

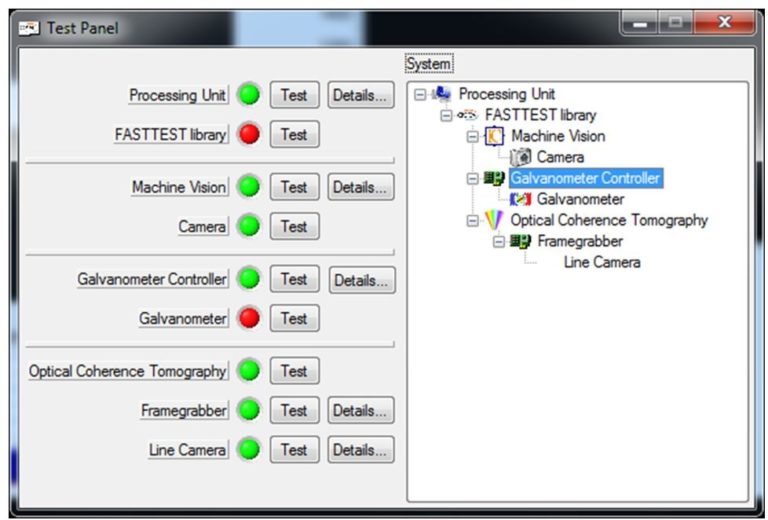

FASTTEST is a fully self-contained system and, as such, has a comprehensive set of automated diagnostic tools for reliable hardware control.

Since the beginning of the project, we at ASE Optics have achieved significant improvements in the FASTTEST instrument, taking it beyond the current SoTA for non-contact micrometer inspection technology. The measurement rates achieved in 3D coupled with the measurement philosophy that drastically reduces the data burden allows for an instrument that can match production rates. A feat not achieved before. A feat not achieved before.This results in faster feedback on drifts in the manufacturing process to the manufacturer, allowing for quicker intervention and therefore reducing waste by allowing process alteration before products go out of specification. This allows FASTTEST customers to save resources and become more efficient. End users also benefit from FASTTEST, they have greater assurance of the quality of the products they are buying. The main market for microdevices currently being disposable point-of-care medical devices, the long-term impact of FASTTEST is improved treatment and ultimately health for Europe and its citizens.

The Secretary of State for Research, Development and Innovation (Ministry of Economy and Competitiveness) awarded ASE Optics Europe the Horizonte PYME grant for the development of FASTTEST, as a new metrology and inspection system aimed at improving the production lines of micro-feature manufacturers.

This grant confirmed the feasibility of the proposal and helped us move forward to complete this ambitious project.