Design of complete and custom-made optical system for cytometer

Our client needed to optimize the optical system of the cytometer prototype he had developed, for the industrialization phase. Their objectives were clear: reduce the size of the equipment, improve image quality and improve image processing, including a custom software development (GUI). ASE Optics was in charge of the entire process: specification review, preliminary optical design, final optomechanical and optoelectronic design, component selection, procurement, assembly, integration, validation and installation and testing at the customer’s premises. Preliminary optical design: overcoming technical challenges to improve optical quality There were two key issues that marked the project:

- The system had to integrate as many catalog elements as possible to optimize costs.

- The optical system, which integrated a 1:1 filter, had to be flexible to adapt to the different image magnification schemes to be transmitted to the sensor.

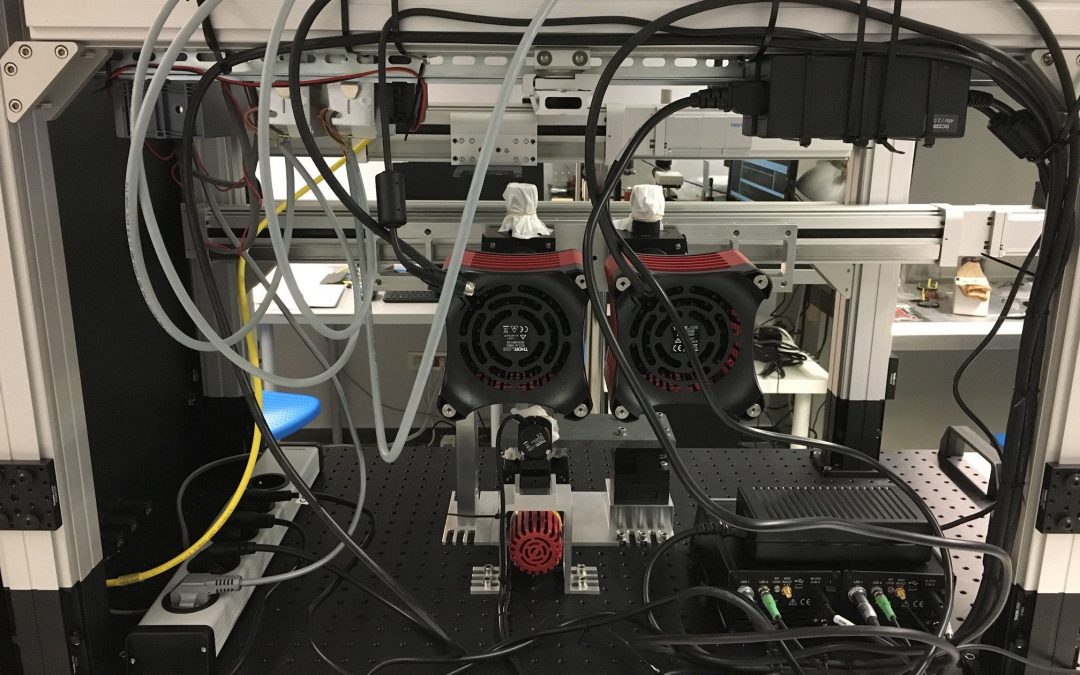

After reviewing the specifications, we found it feasible to redesign the system, also proposing a reduction in the dimensions of the equipment, larger than expected. The final optical design consisted of a multi-element optical system, including an objective and a relay, guaranteeing the expected image quality. In addition, the aspheric surfaces were limited to achieve a significant cost reduction. Design and development of the optomechanics, software development and full integration The second phase of the project consisted of coordinated work between three teams: optical engineering, mechanical engineering and software development. The mechanical engineering team designed the mechanical interface, and defined the final list of materials and components that were to make up the final equipment, in direct collaboration with the optical engineers and the customer. In this way, a complete system was defined, based on catalog elements: LED light sources, filters, optomechanics, electronics… In parallel, we designed and developed a graphical user interface (GUI) for image processing, which we integrated into the final system. System verification, installation and training at the customer’s facilities The last phase of the project was the verification of the system at ASE Optics’ facilities and the subsequent delivery of the system to the customer. On this occasion, two of our engineers went to the customer’s facilities to install the system and to give a training session to their workers, so that they could take full advantage of the equipment.

Our expertise in optical systems for medical equipment and medical applications.

Innovation and development are at the core of ASE Optics’ business, so we constantly apply the latest advances in areas such as detectors, sensors, new materials, optical components, new technologies and improvements in visible, infrared and ultraviolet bands … to the solutions we design for our customers:

- Miniaturization of visualization systems: laryngoscopes, endoscopes, laparoscopes …

- Optical systems for surgical instruments and devices

- Design and development of improved optical subsystems for ophthalmoscopes, retinoscopes,…

- Non-destructive inspection systems based on laser technologies for point-of-care systems and devices

- Tailor-made microscope objectives: tight tolerances, large numerical aperture, special material requirements and specific technical constraints.

- Medical systems based on laser technology.

- Fluorescence imaging systems

- OCT (optical coherence tomography) applied to different medical devices.

- Dental imaging systems and intraoral cameras.