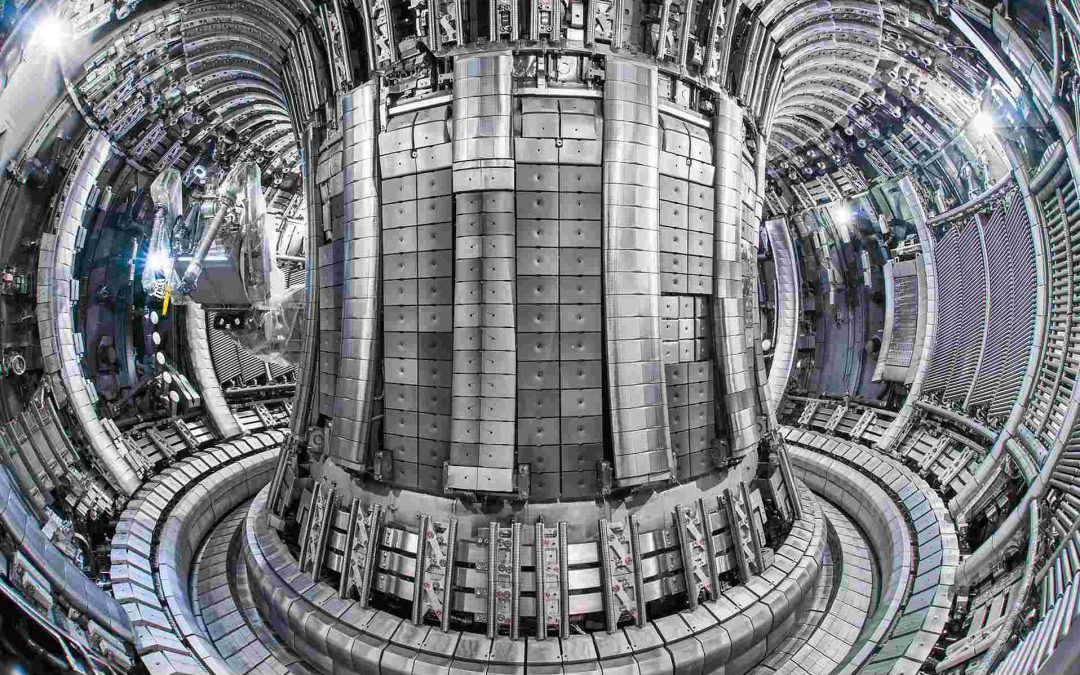

Inspection system for the first prototype of a commercial fusion-based power plant

The UK Atomic Energy Authority’s (UKAEA) Spherical Tokamak for Energy Production (STEP) program is in the process of conceptual design of instrumentation for the first commercial prototype fusion-based power plant. The reactor components are expected to require inspection, routine maintenance and replacement of deteriorated parts. Because of ASE Optics’ previous work over several years on the ITER IVVS (In-Vessel Viewing System) instrument, which allows 3D mapping of the elements inside the Tokamak to detect any damage or erosion of its components, we have been approached by the UKAEA to carry out an analysis of whether this same type of technology could be used in STEP. The purpose of this project is to analyze whether the technology used in the IVVS would be compatible for inspection of the entire inner surface of the STEP reactor. This has involved reviewing both the STEP requirements and the assumed design basis to identify compliance and design customization options. Analysis of STEP environmental and functional requirements In order to perform this review, ASE Optics has analyzed the STEP environmental and functional requirements and presented a comparative analysis with ITER conditions and needs, which will help the UKAEA team to assess the suitability of the IVVS technology for their inspection instrument. In addition, we have analyzed the potential level of coverage as a function of the number of instruments and their position, the accuracy achievable by the measurement and the scanning time of the complete camera or component sections. Project challenges The complexity of these inspection operations depends, to a large extent, on how long the equipment has to operate in the harsh STEP reactor environment, taking into account the harsh environmental conditions in the STEP reactor such as radiation rate, vacuum level, temperature and heat flux and residual magnetic field. As STEP is still in early design phases, some of these requirements still have some uncertainty that carries over to the definition of the inspection system. Results obtained The conclusions of the IVVS technology suitability study for its inspection instrument in STEP have been positive, indicating that most of the functional and environmental requirements of STEP can be met by a lidar technology instrument similar to IVVS. The biggest hurdles would be very strict requirements on maximum temperature and vacuum level inside the chamber. The next steps would be a refinement of the functional requirements and identification of alternative performance options.