Industrial optical inspection

Design, development and manufacturing

Industrial optical inspection

ASE Optics has extensive experience in the development of optical inspection systems for demanding applications. Our customers are companies that offer and market high-precision inspection and measuring machines with complex requirements: high accuracy, customized specifications, deployment in harsh environments.

Optical inspection for semiconductors

Optical diagnostic system

Nondestructive inspection of microdevices and microfluidic devices

Industrial optical inspection

- Optomechanical solutions.

- Implementation of electronic interfaces.

- Software development for image processing and/or process automation.

- Industrialized final production of equipment in series.

Principales ventajas de incluir nuestros sistemas personalizables

- Reduced complexity of assembly and alignment of the final equipment.

- Reduced maintenance requirements.

Optical inspections for semiconductors

We work for companies specialized in the commercialization of inspection and measuring machines for semiconductor components, process monitoring and failure analysis systems, as well as other analytical services.

Developing customized optical subsystems

We help them by developing customized optical subsystems based on lasers and photonics, integrated into the inspection and measurement equipment for:

- Detection, review or inspection of defects, particles, contamination or protrusions.

- Uniformity and film thickness measurements.

- Critical dimensions and overlap measurements.

- Measurements of strain, refractive, reflective and conductivity indices.

- Inspection and metrology of wafers and substrates.

Semiconductor manufacturing is one of the drivers of the world economy and its quality inspection is critical. Optical technologies are one of the key technologies for the various inspection and final measurement systems in the semiconductor industry and, as experts in the design and development of optical and photonic systems, we can offer the optimal solution for each customer.

Flexible solutions for developing optical inspection systems

Innovation and flexibility are the essence of ASE Optics. We provide disruptive, customized and integrated solutions. Taking into account the specific requirements and needs of each case, we cover the entire process, from design to mass production:

- Review and definition of specifications: optics, optomechanics, electronics, sensors, components…

- Complete design and development

- Prototyping

- Mass production

Beyond optics: integrated optical and photonic solutions for inspection and measurement systems

ASE Optics has experience in the development of various laser-based optical systems for semiconductor inspection applications. We are a multidisciplinary team of professionals specialized in different areas:

- Laser technologies: high power lasers, laser system integration, fiber coupling and alignment.

- Electronic integration

- Development of software for image processing and process automation.

We adapt our scope of work to each case, working closely with our clients to offer optimal solutions.

Optical diagnostic systems

At ASE Optics we develop systems for optical diagnostics and non-destructive inspection of large areas and surfaces. Our difference with respect to the systems available on the market? These systems are adaptable to the unique requirements and requirements of each client and project, so we guarantee the results for each application and specific case.

Because non-destructive, non-contact inspection of critical surfaces is one of the technologies of greatest interest in key technology sectors such as the science industry, Fusion, or chip and semiconductor manufacturing.

ASE Optics offers its customers a series of customizable, on-demand optical diagnostic systems.

High precision optical dimensional inspection

One of the solutions developed is a visualization and optical metrology system for scanning and measuring small objects over long distances with high accuracy. By means of raster scanning and 3D reconstruction, any damage or erosion of the components being inspected (walls, surfaces, individual elements) can be detected.

One of the solutions developed is a visualization and optical metrology system for scanning and measuring small objects over long distances with high accuracy.

Reliability and robustness

Therefore, our systems can be adapted to meet complex and highly demanding requirements: vacuum, high temperatures, vibration, high magnetism, sealing…

Reflectivity measurement for large objects and hazardous environments

The original system was developed for ITER: a robust system was needed for the measurement of slabs that had been exposed to radiation. Traditional bi-directional measurement instrumentation could not be used due to the risk of contamination, so ASE Optics developed this new system, currently in use: TARMS.

Our experience

Nuestra capacidad para diseñar, ensamblar y construir sistemas ópticos, fotónicos y láser para la inspección y metrología no destructiva bajo requerimientos y requisitos únicos y muy estrictos ha permitido que podamos participar en otros proyectos como:

- Lithium flow control by means of non-contact measurement systems aimed at optimizing the efficiency of a large scientific fusion facility such as IFMIF-DONES.

- Analysis for the use of our reflectivity measurement system for large objects in hazardous environments intended for use in UKAEA’s first prototype commercial fusion-based power plant.

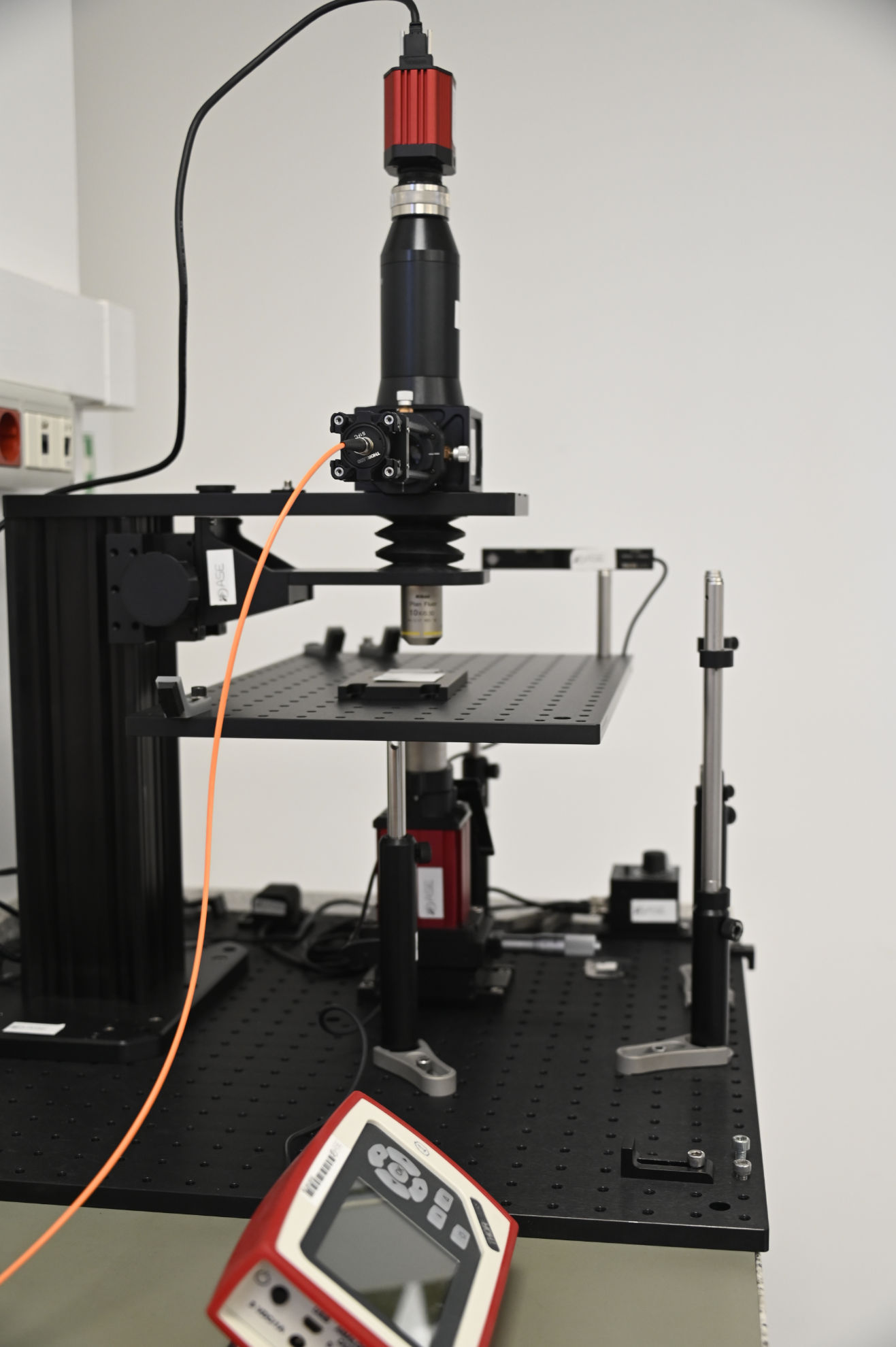

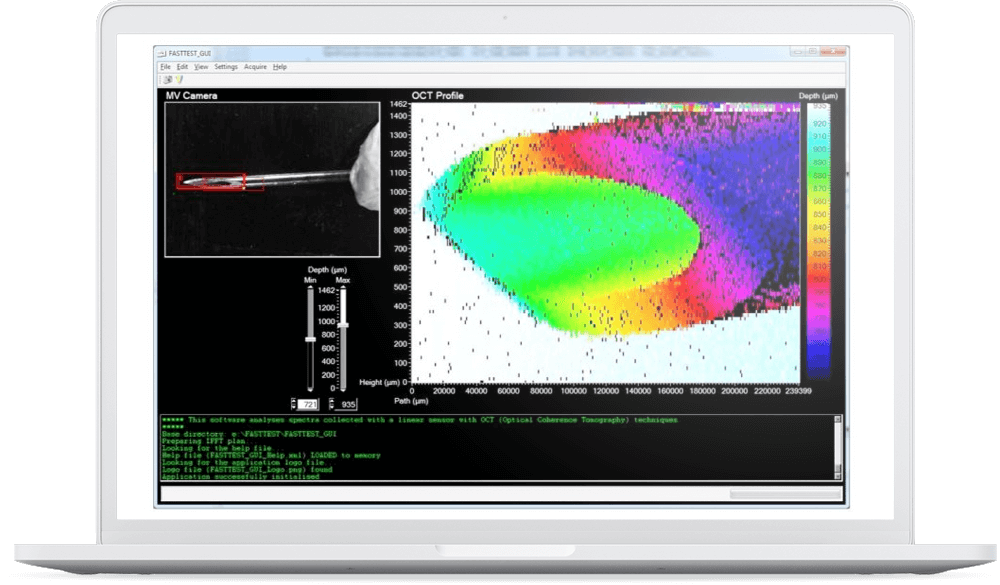

Nondestructive inspection for microdevices and microfluidic devices

If you need a new metrology system for non-contact 3D inspection of microfluidic chips and other microcomponents, we have the solution you are looking for.

ASE Optics proporciona sistemas de inspección no destructiva bajo demanda que ofrecen al fabricante información más rápida sobre las desviaciones en el proceso de fabricación de microdispositivos. This helps them to save resources and be more efficient: it allows faster intervention and therefore a reduction of waste by allowing process alteration before products deviate from specifications.

By implementing our systems on the production line, you receive real-time information about the manufacturing process, quickly detect incidents and obtain valuable reports and data to improve future production, reducing manufacturing costs and increasing the proportion of compliant product suitable for sale and use.

Technical characteristics of the system

- Inspection system designed for integration into the production line

- Combination of OCT and machine vision technology: more efficient data acquisition to match 3D manufacturing speeds

- Solution adaptable to the particularities of each production line

- Hardware and software designed for fast learning to use (“user friendly”)

- Security protocols for both incoming and outgoing data

- Quick and efficient technical support

Benefits: what you get with FASTTEST

The system allows a pre-selection of the inspection zones of interest. This, coupled with a well-optimized data acquisition rate, allows inspection of parts at rates that match production rates, enabling systematic inspection of all production line output rather than randomly selected samples. This comprehensive quality control reduces waste and increases quality in sectors such as point-of-care medicine where disposable microfluidics are used.

What do they say about us?

Here are some reviews from our customers about ASE Optics

ASE Optics has achieved a system that increases magnification by 44% and improves optical quality by an order of magnitude but without changing the overall cost of the product.

The innovation capacity of the ASE Optics Europe team is impressive. Thanks to their contribution, we achieved a viable and 100% novel solution for the optical system of our project.

Follow us on our social networks

You will be able to follow all the news of ASE Optics that we share in the networks.

Contact us

ASE Optics Europe

Carrer Cerdanya, 44

08820 El Prat de Llobregat

Barcelona

Call us at

937 37 98 63

Write to us at

info@aseoptics.com